The world of healthcare is on the cusp of a remarkable transformation, and at the forefront of this change is the burgeoning field of 3D bioprinting. As the medical industry continues to embrace innovative technologies, the potential applications of 3D bioprinting hold the promise of revolutionizing how we approach tissue engineering, organ transplantation, personalized medicine, and regenerative medicine. By 2025, the impact of this cutting-edge technology is expected to be felt across various healthcare domains, from drug testing to wound healing and medical research, as well as the creation of customized prosthetics.

At the heart of this transformation is the process of 3D printing, also known as additive manufacturing. This innovative technique involves taking a digital model or blueprint and printing it in successive layers of an appropriate material to create a new version of the subject. The medical field has seen a significant surge in the utilization of 3D printing, with forecasts indicating that the 3D printing in medical market will be worth a staggering $3.5 billion by 2025, up from $713.3 million in 2016.

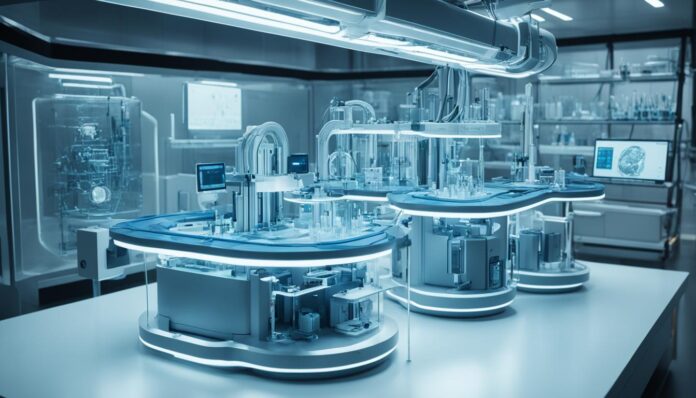

One of the most exciting and transformative applications of 3D printing in healthcare is 3D bioprinting, a specialized form of 3D printing that employs living cells. This revolutionary approach is poised to reshape the landscape of healthcare, offering potential applications in tissue engineering, organ transplantation, personalized medicine, and regenerative medicine. By leveraging bioprinting, researchers and medical professionals can create artificial living tissue and organoids that mimic organs, which can be utilized for medical research, drug testing, and potentially serve as alternatives to traditional human organ transplants.

Beyond the realm of bioprinting, 3D printing technology is also enabling the creation of patient-specific anatomical models, innovative surgical instruments, and customized prosthetics. These advancements have the potential to improve surgical outcomes, reduce recovery times, and enhance the overall quality of patient care. Furthermore, the COVID-19 pandemic has underscored the critical role of 3D printing in addressing supply chain issues, with hospitals relying on this technology to rapidly produce personal protective equipment and medical devices.

Key Takeaways

- 3D bioprinting is revolutionizing healthcare with potential applications in tissue engineering, organ transplantation, personalized medicine, and regenerative medicine.

- Bioprinting can create artificial living tissue and organoids that mimic organs, which can be used for medical research, drug testing, and as alternatives to human organ transplants.

- 3D printing is enabling the creation of patient-specific anatomical models, surgical instruments, and customized prosthetics, improving surgical outcomes and reducing recovery times.

- The COVID-19 pandemic has highlighted the importance of 3D printing in addressing supply chain issues, with hospitals relying on the technology to rapidly produce personal protective equipment and medical devices.

- The 3D printing in medical market is expected to grow from $713.3 million in 2016 to $3.5 billion by 2025, showcasing the significant potential of this technology in the healthcare industry.

3D Bioprinting and Its Role in Revolutionizing Healthcare

The healthcare industry is witnessing a revolution driven by the remarkable advancements in 3D bioprinting technology. This innovative process, which involves using a computer-guided pipette to layer living cells known as bio-ink, is paving the way for groundbreaking applications in tissue engineering, organ transplantation, and personalized medicine.

Bioprinting Tissues and Organoids for Medical Research

The ability to create artificial living tissue and organoids that mimic human organs on a miniature scale has provided researchers with a powerful tool for advancing medical research and drug development. Companies like Organovo are exploring the printing of liver and intestinal tissue to study organs in vitro and develop new treatments for various diseases. Similarly, researchers at the Wake Forest Institute have made significant strides in developing 3D brain organoids with a functional blood-brain barrier, which can be utilized for drug discovery and disease modeling. The University of California Berkeley and other leading institutions have also achieved remarkable breakthroughs in 3D bioprinting techniques, demonstrating the potential to produce on-demand living tissue, blood vessels, bones, and even organs.

Organ Transplantation: 3D Bioprinted Organs as a Potential Solution

While the healthcare industry has not yet achieved the ability to print and successfully transplant a fully functional 3D-printed organ, the potential of this technology to address the shortage of donor organs and improve the organ transplant system is highly promising. 3D bioprinted organs could provide a more accessible and cost-effective alternative to traditional human organ transplants, reducing waitlists and increasing accessibility for patients in need. Moreover, the ability to create customized, patient-specific organs using the recipient’s own cells could minimize the risk of rejection and complications, further improving outcomes.

Personalized Medicine: Custom-Printed Tissues and Implants

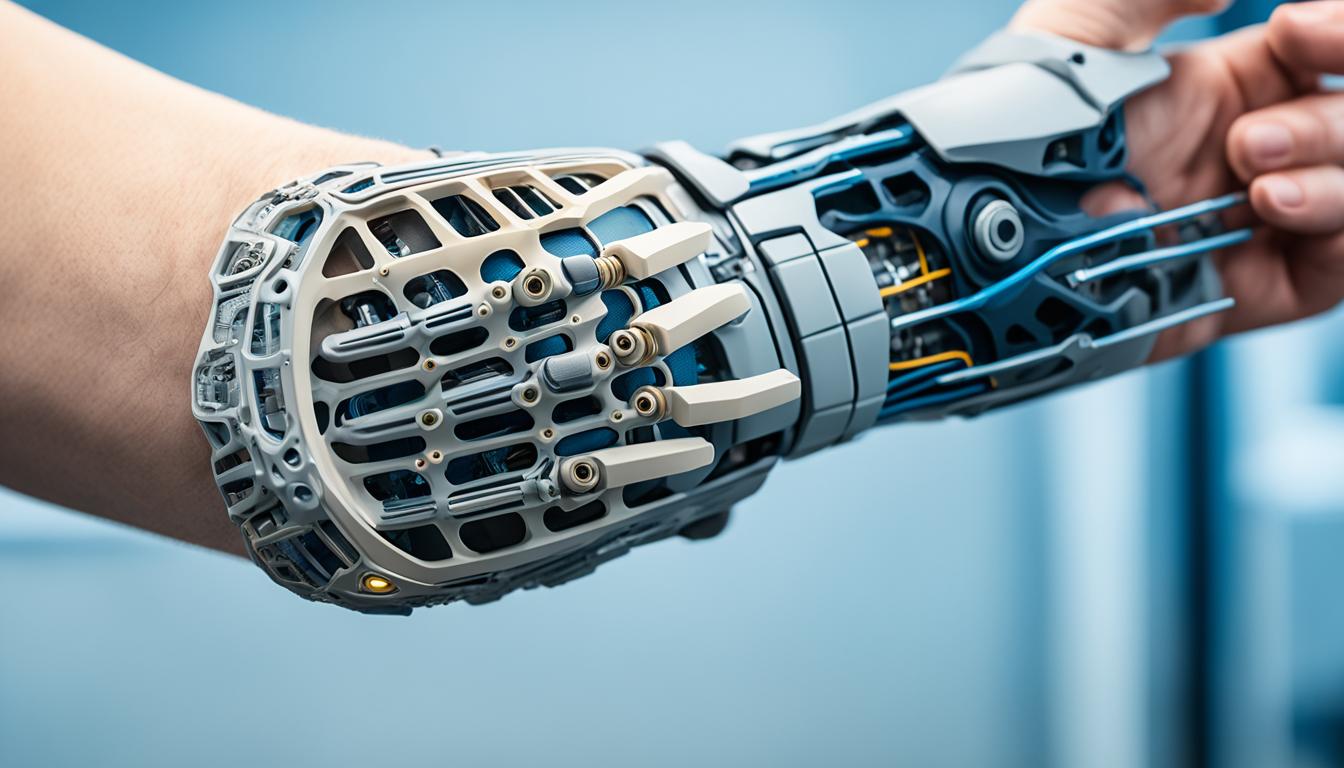

The advancements in 3D printing technology have enabled the production of customized prosthetic limbs, cranial implants, and orthopedic implants like hips and knees, aligning with the ongoing shift towards precision medicine. Customized implants can be designed to perfectly fit each patient, improving the adoption of the implant, reducing the probability of rejection, and preventing complications. The ability to easily modify digital designs allows for the creation of tailored surgical implants and medical devices, further enhancing patient outcomes and minimizing recovery times.

The Expanding Applications of 3D Printing in Healthcare

The healthcare industry has witnessed a profound transformation with the advent of 3D printing technology. Beyond its role in revolutionizing medical research and surgical practices, 3D printing has expanded its reach into various areas, delivering significant benefits to both healthcare providers and patients.

Surgical Preparation with 3D Printed Anatomical Models

One of the most remarkable applications of 3D printing in healthcare is its ability to create highly accurate and detailed 3D printed anatomical models. These models can serve as invaluable tools for surgeons, assisting them in preparing for complex procedures, improving surgical outcomes, and reducing costs. A study found that the use of 3D-printed anatomical models as surgical guides reduced the average procedure length by over an hour, resulting in a cost savings of $3,720 per case. Another study concluded that lengthy surgeries were reduced by 1.5 to 2.5 hours when 3D-generated anatomical models were used as guides, allowing hospitals to schedule more surgeries and shorten waitlists. Additionally, 3D printed anatomical models can be a valuable learning resource for medical students and residents, helping them better understand complex anatomies and procedures.

3D Printed Medical Equipment and Prosthetics

The versatility of 3D printing has also enabled the fabrication of customized medical devices, such as forceps, clamps, hemostats, and retractors. This allows for rapid design modifications based on surgeon feedback, ensuring the equipment meets the specific needs of healthcare professionals. Furthermore, the ability to quickly produce medical equipment and devices using 3D printing has been instrumental in addressing supply chain challenges, particularly during the COVID-19 pandemic. Additionally, 3D printing can be leveraged to create customized, low-cost prosthetic limbs that are tailored to the individual user, improving functionality and accessibility, especially for children who quickly outgrow traditional prosthetics. The flexibility and cost-effectiveness of 3D printing have made it a valuable tool in expanding access to medical equipment and prosthetics, helping to address healthcare disparities.

Conclusion

3D bioprinting and 3D printing have revolutionized the healthcare industry, transforming medical research, surgical practices, and patient care. From bioprinting tissues and organoids for medical research and potential organ transplants to creating customized surgical implants and prosthetics, this innovative technology is enhancing precision medicine and improving patient outcomes.

The ability to rapidly produce anatomical models, medical devices, and equipment has also helped address supply chain issues, particularly during the COVID-19 pandemic, underscoring the value of 3D printing in the healthcare sector. While this technology faces challenges, such as upfront costs and regulatory concerns, the industry’s continued advancement and the growing number of hospitals with in-house 3D printing facilities suggest that the potential applications of 3D printing will only continue to expand by 2025 and beyond.

As the healthcare industry embraces the power of 3D printing, you can expect to see even more remarkable advancements in medical research, surgical procedures, and personalized patient care. The future of healthcare is being shaped by this transformative technology, and the possibilities are truly exciting.

FAQ

What are the potential applications of 3D bioprinting in healthcare by 2025?

3D bioprinting, a specific type of 3D printing that uses living cells, is revolutionizing healthcare with potential applications in tissue engineering, organ transplantation, personalized medicine, and regenerative medicine. Bioprinting can create artificial living tissue and organoids that mimic organs, which can be used for medical research, drug testing, and potentially as alternatives to human organ transplants.

How can 3D bioprinting impact organ transplantation?

While the healthcare industry has not yet achieved the ability to print and transplant a functional 3D-printed organ, many experts are optimistic about the potential of this technology to address the shortage of donor organs and improve the organ transplant system. 3D bioprinted organs could provide a cheaper and more accessible alternative to human organ transplants, reducing costs, shortening waitlists, and increasing accessibility for patients in need.

What are the benefits of 3D printing in personalized medicine?

3D printing technology has enabled the production of customized prosthetic limbs, cranial implants, and orthopedic implants like hips and knees, aligning with the ongoing shift towards precision medicine. Customized implants can be designed to perfectly fit each patient, improving the adoption of the implant, reducing the probability of rejection, and preventing complications.

How can 3D printing enhance surgical outcomes?

3D printing can produce highly accurate and detailed anatomical models, which can assist surgeons in preparing for complex procedures, improving outcomes, and reducing costs. A study found that the use of 3D-printed anatomical models as surgical guides reduced the average procedure length by over an hour, resulting in a cost savings of ,720 per case.

What are the other applications of 3D printing in healthcare?

3D printing has enabled the fabrication of customized medical devices, such as forceps, clamps, hemostats, and retractors, allowing for rapid design modifications based on surgeon feedback. The ability to quickly produce medical equipment and devices using 3D printing has been instrumental in addressing supply chain challenges, particularly during the COVID-19 pandemic. 3D printing can also be used to create customized, low-cost prosthetic limbs that are tailored to the individual user, improving functionality and accessibility, especially for children who quickly outgrow traditional prosthetics.